Multiwall Paper Sacks

To suit everyone’s need

The type of multiwall sack to be used for a certain application depends on a number of factors, including, the physical characteristics of the type of product to be packed, the way in which it will be transported, stored and distributed, and the way in which it will be used by the final customer, amongst other things. Each variant has its advantage of custom design barriers offering different size packaging for different net weights of product, and excellent print graphics for shelf appeal, thus making multiwall sack the most preferred flexible packaging product.

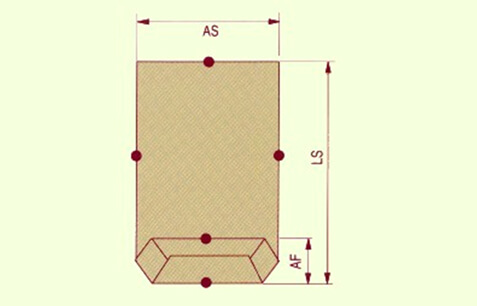

Open mouth, Pasted bottom Sack

Advantages:

It doesn’t require a special packing machine to be filled. It allows the insertion of an interior plastic liner.

Disadvantages: Quality of palletizing is only fair because the sack is not symmetrical. Requires some sort of closure once the sack is filled.

Main uses: Powdered milk, Starch, Wheat Flour, Minerals, Plastic Resins. Also as a container of smaller units (noodles, flour, rice)

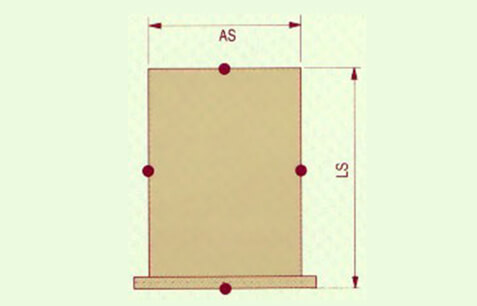

Open Mouth Sewn Bottom Sack

Advantages:

It doesn’t require a special packing machine to be filled. It allows the insertion of an interior plastic liner.

Disadvantages: Forms unstable pallets because the filled sack resembles a “pillow”. Requires some sort of closure once the sack is filled.

Main uses: Corn Seeds, Fertilizers, Wheat Flour, Oats.

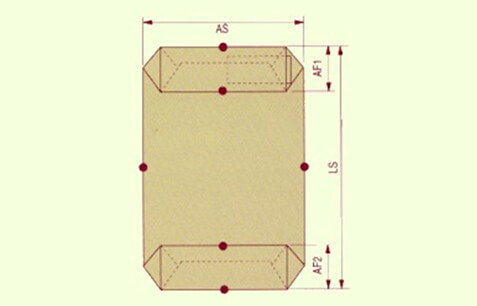

Valved, Pasted Bottom Sack

Advantages:

Palletizing is very stable because the filled sack resembles a block. The valve closes due to the internal pressure of the product, and for that reason, it doesn’t require closing after filling. Designed for high-speed automatic or semi-automatic packing machines.

Disadvantages: Requires a special packing machine to be filled. Not possible to insert a plastic liner.

Main uses: Cement, Mortars, Chemical Products, Sulphur, Plaster.

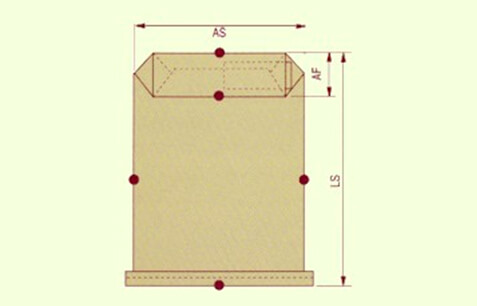

Sewn Valve Sack

Advantages:

The valve closes due to the internal pressure of the product, and for that reason, it doesn’t require a closing after filling. The sack can be opened easily at the sewn end.

Disadvantages: Requires a special packing machine to be filled. Not possible to insert a plastic liner. Quality of palletizing is only fair because the sack is not symmetrical.

Main uses: Wheat Flour, Pharma Products

Multiwall Advantages

Multiwall paper bags are scientifically proven to:

- Preserve freshness

- Reduce Infestation

- Resist moisture

- Lock in odour

- Reduce or eliminate chemical preservatives.

Multiwall paper bags can be easily transported by truck and containers, for shipments. Here is a sample of paper bag design characteristics:

- Basic raw material is a renewable resource.

- Protects contents from the absorption of moisture

- Prevents loss of essential moisture from contents

- Permits top icing of fresh produce

- Prevents the escape of oils or flavours from products

- Protects against chemical action of contents

- Prevents seepage or penetration of products packed “hot”

- Prevents low-cost protection against contamination

- Permits stacking for better utilization of warehouse space

- Serves as a degradable package under certain conditions

- Has the FDA approval for food packing.